Mining in the 21st century is no longer defined solely by the size of deposits or the volume of proven reserves, but also by the sophistication of industrial processing.

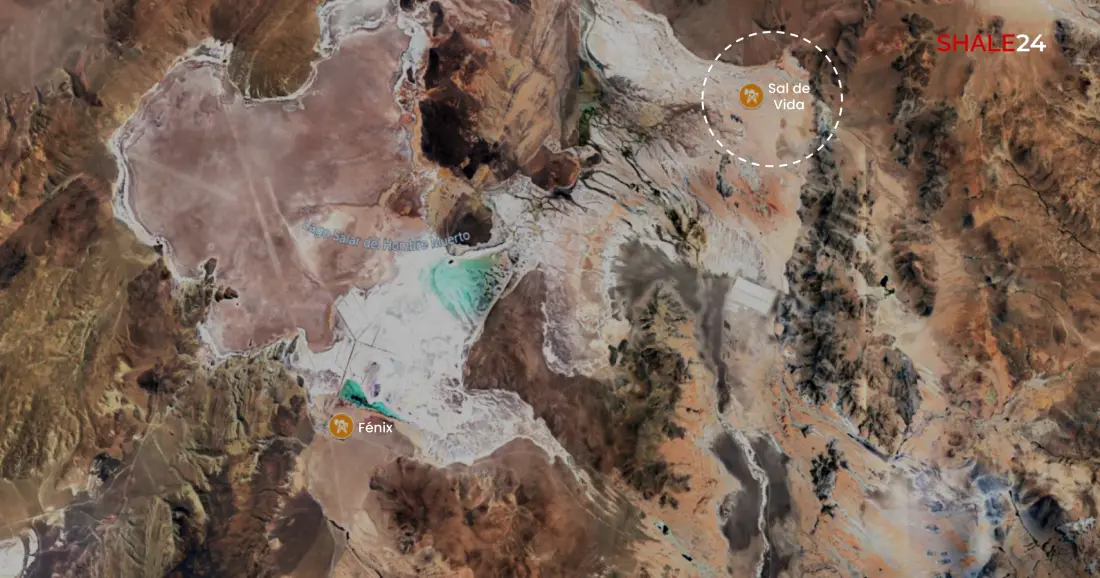

The Salar del Hombre Muerto, in the high-altitude Puna region of Argentina’s Catamarca province, has emerged as the setting for a paradigm shift that could redefine the country’s competitiveness in the global critical minerals market. Anglo-Australian mining giant Rio Tinto has announced the deployment of a pilot Direct Lithium Extraction (DLE) unit, developed by U.S.-based ILiAD Technologies, at its Sal de Vida project.

The partnership is not only an operational milestone but also a statement of intent on how cutting-edge technology and sustainability can converge to accelerate production of “white gold,” a key input for the energy transition and the expansion of electrification.

Samuel Moore, chief executive of ILiAD Technologies, said: “We are excited to transition into this in-field program with Rio Tinto. Our latest advancements in DLE offer meaningful project savings, and this test deployment allows us to demonstrate that performance directly.”

Barbara Fochtman, managing director of Rio Tinto Lithium, added: “This pilot represents an important next step in our collaboration with ILiAD. With more than 30 years of experience operating DLE at commercial scale, we have the expertise to evaluate new technologies and integrate them with proven processes. That combination is essential to advancing efficient and sustainable lithium production.”

What is Direct Lithium Extraction, and why is it a technical disruption?

Traditionally, lithium production from brines relies on vast solar evaporation ponds. The process is inherently slow, requiring between 12 and 24 months for sun and wind to concentrate the mineral, and recovery rates rarely exceed 50%. By contrast, Direct Lithium Extraction functions as a high-precision “molecular filter.”

ILiAD’s technology uses a selective adsorption platform that captures lithium ions from brine almost instantaneously, while responsibly returning the remaining components to the aquifer.

From an industrial efficiency standpoint, the technical benefits are substantial. First, lithium recovery rates can exceed 90%, nearly doubling the output of evaporative methods.

Second, processing time is reduced from months to hours, enabling a more agile response to market demand fluctuations. In addition, by eliminating the need for large evaporation ponds, the project’s physical footprint is dramatically reduced, minimizing visual and environmental impacts on the fragile ecosystems of the Puna plateau.

Sal de Vida: Rio Tinto’s strategic pillar in Argentina

The Sal de Vida project is positioned as a crown jewel in Rio Tinto’s asset portfolio following its acquisition of Arcadium Lithium. Located in one of the world’s most lithium-rich regions, the deposit stands out not only for its scale but also for the chemical purity of its brine, which has notably low impurity levels and facilitates processing to battery-grade material.

From an investment and reserves perspective, Sal de Vida is a world-class project. Rio Tinto has submitted plans under Argentina’s Large Investment Incentive Regime, known by its Spanish acronym RIGI, which include an initial investment of approximately $638 million to advance the asset.

Proven reserves and indicated resources support a mine life exceeding 40 years. The initial operating plan targets annual production of 15,000 metric tons of lithium carbonate equivalent, with significant potential to scale up as ILiAD’s DLE technology is integrated at industrial scale.

Sustainability and the future: the Catamarca–ILiAD Technologies synergy

The deployment of ILiAD Technologies’ pilot plant at Sal de Vida has a clear objective: to validate lithium recovery efficiency under the specific conditions of Catamarca’s brine.

The technical rollout aims to optimize water use, one of the most sensitive issues for mining in arid regions. ILiAD’s technology enables a more circular approach to water management, reducing freshwater consumption and maintaining the salar’s hydrogeological balance through reinjection of depleted brine.

This approach responds not only to technical performance requirements but also to growing demands from international markets for lithium with verified environmental traceability.

Through this project, Catamarca positions itself at the forefront of sustainable mining, demonstrating that it is possible to attract capital-intensive investment while applying technological standards that protect the natural environment.

The consolidation of Sal de Vida, combined with other company projects such as Rincón in Salta province, positions Rio Tinto as a dominant player that could control a substantial share of global lithium supply by the end of the decade.

The deployment of ILiAD’s pilot plant is, ultimately, the opening chapter of a new era for the Lithium Triangle, the region spanning parts of Argentina, Chile and Bolivia. The ability to transform brine into high-purity battery material for electric vehicles quickly, efficiently and with environmental responsibility could be the key to unlocking a global energy transition led from northern Argentina.